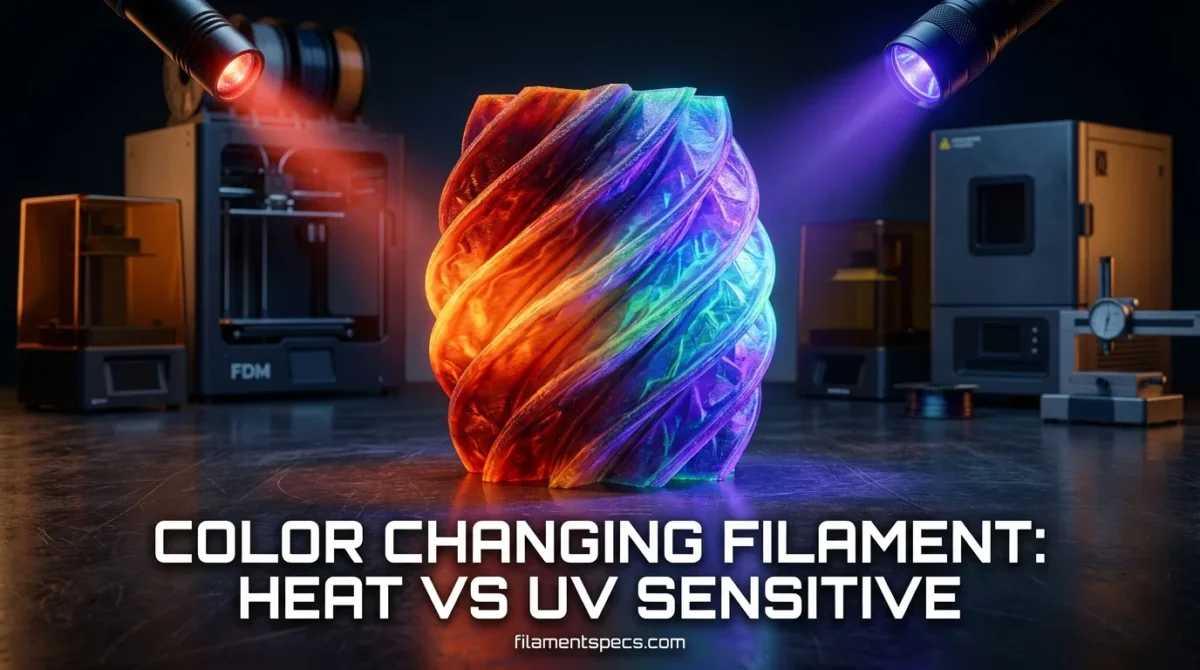

Color-changing filament is one of those “looks like magic” materials that’s actually built on very real chemistry. In 3D printing, you’ll mostly meet two families: heat-sensitive (thermochromic) and UV-sensitive (photochromic). They can look similar in a short video, yet they behave differently in daylight, indoors, under a lamp, or even after a long print. This guide treats them like materials, not gimmicks—how they work, what makes them stable, what makes them drift, and how to pick the right type for the job.

One practical detail: “UV-sensitive” usually means it changes under the same ultraviolet band that drives the UV Index math—UVA and UVB in the 280–400 nm window. [c]

| Aspect | Heat-Sensitive Filament (Thermochromic) | UV-Sensitive Filament (Photochromic) |

|---|---|---|

| Trigger | Temperature change (surface warming/cooling) | UV exposure (commonly within 280–400 nm; UVA/UVB bands) |

| Where The Effect Shows Up First | Areas that warm fastest (fingers, hot air, nearby electronics, sunlight-heated surfaces) | Outer surfaces hit by UV (sun-facing walls, top layers, thin shells) |

| Reset Behavior | Returns when the material crosses back through its switching region | Fades back when UV is removed (often aided by time and ambient temperature) |

| Best At | Interactive touch effects, thermal gradients, “heat map” style prints | Outdoor “sun reveal” prints, UV-reactive signage, daylight-triggered accents |

| What Commonly Limits Consistency | Uneven heat flow, long nozzle dwell time, heat buildup on large parts | UV not reaching inner walls, indoor lighting lacking UV, surface aging |

| Design Lever That Matters Most | Thermal path: wall thickness, infill, airflow, contact points | UV path: shell thickness, pigment loading, surface finish |

Table of Contents

🧪 What Color-Changing Filament Actually Is

In chemistry terms, thermochromism is a thermally induced, reversible change in a system that produces a spectral shift—often visible color, but not always. [a] In 3D printing filament, you’re not swapping pigments mid-print; you’re printing a polymer that contains additives whose optical behavior changes when they receive a stimulus.

What “Color Change” Can Mean on a Printed Part

- Two-state shift: one color to another, or colored to near-clear.

- Continuous gradient: a smooth transition as temperature or UV intensity varies across the surface.

- Surface-weighted effect: looks strong on thin walls and soft on thick shells, even with the same filament.

🔥 Heat Sensitive Filament Chemistry

Most heat-sensitive filaments rely on microencapsulated thermochromic systems. A common architecture is the “three-component” approach: a color former (dye), a color developer, and a solvent-like component whose phase behavior controls whether the dye and developer interact strongly enough to show color. In one published microcapsule system, the core used a dye (CK-16) with bisphenol-A as developer and a tetradecanol/hexadecanol mixture as co-solvent, and the microcapsules showed an obvious color change around 40 °C. [e]

What Controls The “Switch Temperature”

- Solvent blend (and its melting/freezing behavior)

- Developer strength (how strongly it stabilizes the colored form)

- Microcapsule wall (diffusion barrier and thermal buffering)

What You’ll Notice On Prints

- Finger warmth can create crisp “touch reveals” on thin shells.

- Heat pooling on thick parts can cause slower, softer transitions.

- Airflow changes the look: strong cooling fans often sharpen boundaries.

Thermochromic Filament Behavior That Matters In Practice

- Transition width: the change rarely flips at a single temperature. Expect a band where both states appear as a gradient.

- Thermal hysteresis: heating and cooling can produce slightly different “on/off” points, so the same part can look different when warming versus cooling.

- Thermal history: long prints can raise part temperature; the color can drift while printing even if the room stays constant.

☀️ UV Sensitive Filament Chemistry

UV-sensitive filaments are built on photochromism: a reversible transformation between two forms with different absorption spectra, triggered by irradiation. The back reaction can be thermal or photochemical, and a key durability metric is how many cycles the system can repeat under defined conditions. [b]

Common Photochromic Families You’ll See Mentioned

- Spiropyrans / Spirooxazines: popular for clear-to-color and vivid reveal effects.

- Diarylethenes: known in research for strong switching and good fatigue resistance in certain designs.

- Naphthopyrans: widely used in optical applications where outdoor activation matters.

🔦 Wavelengths and Light: Why Sun Works and Some Lamps Don’t

“UV” is not one thing, and photochromic systems are picky about which wavelengths they absorb. In one ChemComm study, azobenzene switching was driven with 350–380 nm light, while spiropyran-type systems showed strong absorption bands in the UV (roughly 270–350 nm) and a visible band around 550–600 nm once in the colored form. [d]

Indoor reality check: many “daylight” LEDs emit very little UV, so a UV-sensitive print may look calm indoors and then pop outdoors. This is normal, not a defect.

🧩 How Prints Behave: Geometry, Shells, and the “Where Does The Effect Live?” Problem

Heat and UV move through a printed part in very different ways. Heat conduction can spread inward through walls and infill, while UV is mostly a surface story because pigments and the polymer matrix absorb or scatter it. That’s why two prints with the same filament can look dramatically different if one has thin shells and the other has thick outer walls.

| Design Choice | Heat-Sensitive Filament Tends To Do | UV-Sensitive Filament Tends To Do |

|---|---|---|

| Thin walls (single/perimeter focus) | Fast touch response; crisp gradients | Strong activation; color looks “cleaner” and more even |

| Thick shells (many perimeters) | Slower change; heat can linger and “soften” the boundary | Outer layer changes first; inner layers may stay in the base state |

| High infill density | Stores heat longer; can shift the resting look after handling | Usually minor impact unless it changes surface thickness |

| Matte vs glossy surface | Mostly cosmetic; thermal behavior is geometry-driven | Surface scattering can change perceived saturation of the revealed color |

Process Variables That Usually Matter More Than People Expect

- Cooling strategy (fan strength and direction): changes thermal gradients for thermochromic prints and can change surface finish for UV-sensitive ones.

- Part temperature during long jobs: large flat surfaces can warm up simply from time under the nozzle, shifting heat-sensitive appearance.

- Outer wall count: one of the strongest levers for UV-sensitive visibility and “depth” of the effect.

📏 Measuring Performance Without Guesswork

If you want consistent comparisons, treat color change like a measurable response, not a vibe. In photochromic systems, the literature focuses on parameters such as fatigue (chemical degradation), number of cycles, and kinetic ideas like half-life during fading. [f]

Metrics That Translate Well To 3D Prints

- Activation contrast: difference between base and triggered states (a simple before/after measurement works).

- Time-to-peak: how long until the strongest color shows, under a repeatable stimulus.

- Recovery time: how long it takes to fade back when stimulus is removed.

- Cycle stability: run the same stimulus several times and see if the peak keeps dropping.

🛡️ Durability and Storage: Keeping The Effect Looking “Fresh”

Both families can change over time, usually in gentle ways: slightly lower peak saturation, slower switching, or a higher “effort” needed to trigger. In organic polymer-based thermochromic systems, photodegradation from photoexcitation is a known focus of research, and encapsulation approaches are often discussed as ways to improve stability. [g]

- Storage: keep spools away from direct sunlight and strong UV sources; store dry like any filament.

- Surface protection: a clear, compatible topcoat (when appropriate for the polymer) can reduce surface wear and slow visual drift.

- Realistic expectations: color-changing additives are doing extra work; a small amount of change over long use is normal across many chromic systems.

🧠 Choosing Heat vs UV Sensitive Filament

Pick Heat-Sensitive When

- You want touch interaction or heat-gradient art.

- The piece will live indoors with stable lighting.

- You can design for thin, responsive surfaces.

Pick UV-Sensitive When

- You want an outdoor reveal effect in sunlight.

- The print needs to react to environmental exposure rather than touch.

- You can keep outer shells thin enough for UV to do its job.

❓ FAQ

Can a filament be both heat-sensitive and UV-sensitive?

Yes. It’s possible to blend different chromic additives into one polymer. In practice, combined systems can be harder to tune because temperature, UV intensity, and surface thickness can all compete to define what you see at any moment.

Why does my UV-sensitive print barely change indoors?

Many indoor light sources emit little UV. If the pigment isn’t receiving the wavelengths it needs, it will stay near its base state. Outdoors, sunlight provides a stronger UV component and the change becomes obvious.

Why does only the surface change color on UV-sensitive prints?

UV is absorbed and scattered by the polymer and the pigment, so it tends to act like a surface stimulus. Thin shells show stronger, more uniform changes; thick shells often look “skin-deep.”

Do heat-sensitive prints need a heated bed?

Bed heating is mainly about print adhesion and warp control for the base polymer. The thermochromic effect is about the part’s surface temperature in use. Choose bed settings based on the filament’s base material and spool guidance.

Can long prints affect the final look of heat-sensitive filament?

Yes. Large or slow prints can warm the part gradually from repeated toolpath passes. That can soften gradients or shift what “resting color” looks like right after printing, especially on thick geometry.

Is the color change permanent?

Most consumer heat- and UV-sensitive filaments are designed to be reversible. Over long use, the peak effect can slowly soften depending on exposure history, storage, and surface wear, but the intent is repeated switching.

📚 Sources

- [a] IUPAC Gold Book: Thermochromism (definition, PDF)

- [b] IUPAC Gold Book: Photochromism (definition + notes on cycles, PDF)

- [c] US EPA: UV Index page (UVA/UVB wavelength ranges used in calculations)

- [d] Royal Society of Chemistry (ChemComm, 2025): Photochromic compounds in polymer solutions (example wavelength bands)

- [e] Springer (Journal of Thermal Analysis and Calorimetry): Thermochromic microcapsules (three-component core; color change near 40 °C)

- [f] IUPAC Technical Report (Pure and Applied Chemistry, 2001): Organic photochromism (fatigue, cycles, half-life concepts)

- [g] Springer (Journal of Coatings Technology and Research): Review on organic polymer thermochromic materials (photodegradation and stabilization approaches)