| Filament Type | Most Common “Aging” Driver | Typical Print Symptom When Affected | Usually Recoverable by Drying? | Storage Priority |

|---|---|---|---|---|

| PLA / PLA+ | Moisture uptake + heat history | Extra stringing, matte patches, occasional tiny bubbles | Often yes (if the spool hasn’t been overheated) | Seal + desiccant, avoid warm rooms |

| PETG | Moisture uptake | Pop sounds, micro-voids, rough walls, inconsistent extrusion | Often yes | Dry box during printing helps a lot |

| ABS / ASA | Heat + light exposure + moderate moisture | Surface haze, brittle spots on old spools, color shift over time | Sometimes (moisture part), light/heat changes are not “undone” | Dark, cool storage; sealed is best |

| TPU (flex) | Moisture uptake | Spitty extrusion, fuzzy surfaces, weak layer bonding | Often yes | Keep sealed between prints |

| Nylon / PA | Fast moisture uptake | Steam bubbles, severe roughness, soft/variable extrusion | Often yes, but it may re-absorb fast | Dry box or sealed container during printing |

| PVA / BVOH (supports) | Very high moisture uptake | Clogs, swelling, messy extrusion, inconsistent supports | Sometimes (depends on how long it stayed wet) | Seal immediately; store like “lab material” |

| Filled (CF/GF/wood/metal) | Base polymer moisture + filler effects | Abrasive wear, uneven texture, moisture bubbles (depends on base) | Often yes (moisture), texture varies by blend | Treat like the base polymer; keep clean |

“Expire” usually means print quality becomes unpredictable, not that the filament suddenly becomes unusable. The biggest culprit is moisture; real chemical aging is slower but can happen with heat and light.

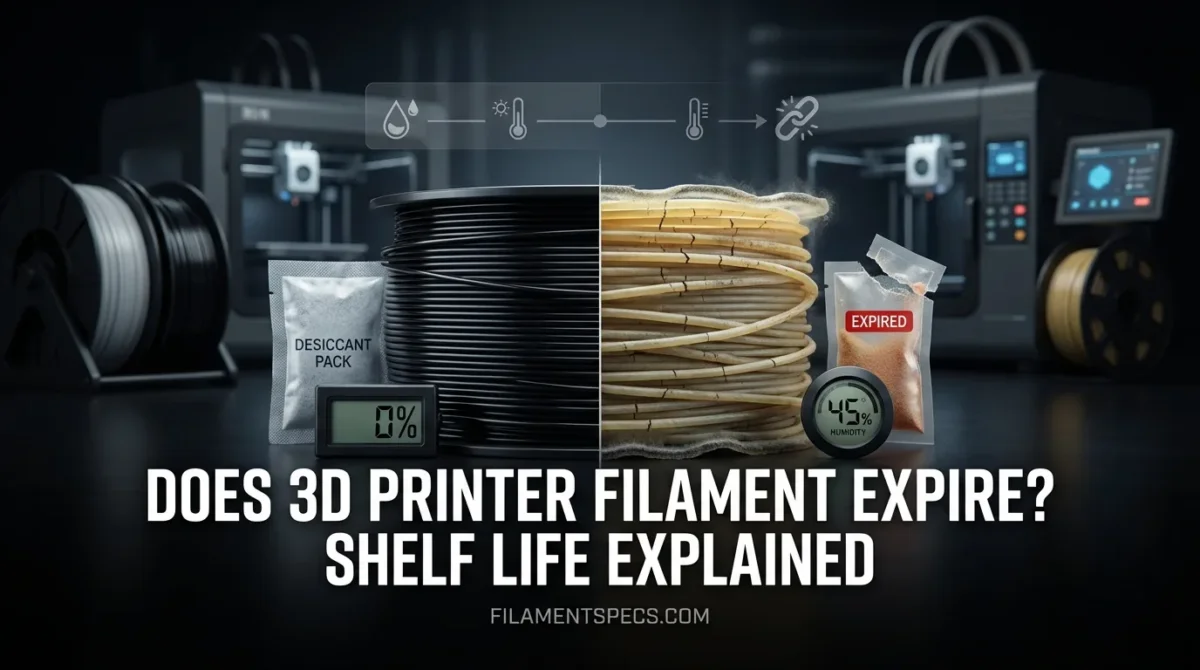

3D printer filament doesn’t “expire” like food, but it can absolutely change in ways you’ll feel at the nozzle. In real life, “expired filament” means loss of consistency: the same settings that worked last month suddenly give rough walls, popping, brittle strands, or weak layers. Most of the time, the villain is humidity, and that’s good news because it’s often fixable with proper drying and smarter storage.[a]

Simple truth: a spool can sit on a shelf for years and still print great if it stays dry, cool, and out of sun. The same spool can act “ruined” after a short time in damp air. Storage controls shelf life.

Table of Contents

🧵 Does Filament Expire, or Just Change Over Time?

Most filament spools do not have a strict “use by” moment. What people call “expiration” is usually one of these situations:

- Moisture-related printing problems (often reversible): water absorbed from air flashes into steam inside the hotend, disturbing extrusion.

- Handling and contamination (often preventable): dust, oils, or debris ride into the nozzle and cause clogs or rough flow.

- Slow material aging (sometimes irreversible): heat and light can trigger chemical changes that don’t “dry out.”

What “Shelf Life” Really Means in 3D Printing

Think of shelf life as “how long the filament keeps printing predictably.” If you store filament at stable temperature, low humidity, and away from direct light, the usable window gets long. If you leave it in open air, shelf life can shrink dramatically, especially for hygroscopic materials (those that readily absorb water).[c]

🧪 Why Filament Performance Changes

Several mechanisms can be at play, but two dominate daily printing: moisture uptake and exposure history (heat + light + time). Here’s what actually happens, in plain terms.

Moisture Uptake (The Biggest Day-to-Day Cause)

Many polymers absorb water molecules into their structure. When that damp filament gets pushed through a hot nozzle, water can expand into steam. The result is messy, inconsistent melt flow: popping sounds, tiny voids, rough walls, and weaker bonding between layers. Some filaments also become more flexible or “rubbery” while wet (classic with nylon).[g]

Hydrolysis (Moisture + Heat = Chain Cutting in Some Polymers)

For polyesters like PLA, moisture and heat can contribute to hydrolysis, which can reduce molecular weight over time. Lower molecular weight can mean more brittle behavior and less stable extrusion under the same conditions. It’s not a scare story; it’s just polymer chemistry, and it’s one reason dry storage matters even if a spool “looks fine.”[b]

Light and UV (Slow, Quiet, and Real)

UV and strong light can trigger photodegradation pathways in polymers, often through oxidation reactions. The practical signs are subtle: color shift, surface dulling, and gradual loss of toughness. This matters most when spools sit near windows, under bright lamps, or in clear containers without protection.[d]

Small but useful rule: if you can see sunlight hitting the spool, the spool can “see” that sunlight too. Keep filament in the dark unless you’re actively printing.

ABS and Surface Yellowing (A Common Example)

ABS is often discussed as “stable,” yet photo-oxidation can still cause visible yellowing at surfaces after UV exposure. That surface change is one of the practical signs that light exposure isn’t just cosmetic.[e]

🧬 Shelf Life by Filament Material

Different materials “age” differently because their chemistry interacts with water, heat, and light in different ways. The most useful way to think about it is moisture sensitivity rather than calendar time. Here’s a practical breakdown that stays accurate across brands and blends.

Moisture Sensitivity Meters (Practical Printing View)

PLA and PLA+

PLA is often forgiving, which is why it tricks people into thinking it’s “immune” to storage problems. It’s not. PLA can absorb enough moisture to create surface artifacts and inconsistent flow, and moisture + heat exposure can nudge long-term changes. If you store PLA sealed with desiccant, it tends to stay stable for a long time. If you leave it out, it’s the classic “it printed fine yesterday” spool.

PETG

PETG is more obviously affected by moisture than PLA. Wet PETG often shows micro-bubbles and roughness that can look like under-extrusion or temperature issues. Dry PETG usually returns to smooth, consistent extrusion, which is why a dryer or dry box can feel like “upgrading” your printer without touching hardware.

ABS and ASA

ABS and ASA are generally less moisture-hungry than nylon, but they still benefit from dry storage. What matters more with ABS/ASA is light and heat history. ASA is often chosen for better outdoor performance, yet spools still deserve dark, cool storage. If a spool has spent months near strong light, the “fresh” feel can fade gradually.

TPU (Flexible Filaments)

TPU loves to pick up moisture, and it shows. Wet TPU can extrude with a “spitty” look, leaving a fuzzy skin and softer details. Keep TPU sealed between prints, and if it starts behaving weirdly, drying is often the fastest fix.

Nylon (PA)

Nylon is the poster child for hygroscopic behavior. It can absorb water from air and change feel and print behavior quickly, sometimes within the “normal hobby timeframe.” The upside is that nylon also responds well to controlled drying, but it may re-absorb moisture fast if left out. If you print nylon often, treat a dry box like a core tool, not an accessory.[g]

🔍 Symptoms of “Expired” Filament

Filament problems can look like slicer problems, so it helps to recognize patterns. These are the most common signs that a spool needs attention:

- Popping or crackling during extrusion (often steam escaping).

- Rough or sandy walls, tiny pinholes, or scattered bubbles.

- Inconsistent extrusion that comes and goes even when temperatures are stable.

- Sudden stringing increase that doesn’t respond to normal tuning.

- Filament that snaps too easily when gently bent (common with older PLA blends, but settings and diameter also matter).

- Support materials (PVA/BVOH) swelling, clogging, or turning “sticky” in the feed path.

- Fast Home Check: “Extrude and Listen”

- Heat the nozzle for that material and extrude 60–100 mm slowly. If it sounds like frying or you see visible micro-bubbles in the strand, moisture is a strong suspect.

- Fast Home Check: “Surface Under a Lamp”

- Compare a new extrusion strand to a known-dry spool. Wet filament often looks duller and less uniform because steam and inconsistent flow create micro-voids.

- Reality Check

- Not every defect is moisture. A partial clog, a worn nozzle, or incorrect temperature can mimic the same symptoms. Moisture is common, so it’s worth ruling out early.

Why moisture is tricky: the spool can feel “normal” in your hand yet still carry enough water to disrupt extrusion. That’s exactly why people label it “expired.”[a]

📦 Storage That Extends Shelf Life

Good storage is not fancy. It’s just consistent. The goal is to slow moisture uptake and avoid light/heat stress. If you do these few things, shelf life becomes much less dramatic.

- Seal the spool when you’re not printing. A thick zipper bag works; a rigid container works too.

- Add desiccant. If you can, use a humidity indicator so you know when it’s time to refresh or replace.

- Keep filament away from sunlight and strong UV sources. Dark storage is a quiet win.

- Avoid hot storage locations (near heaters, radiators, or warm electronics cabinets). Heat accelerates slow changes.

- Keep the spool clean. Dust on filament becomes dust in the hotend, and that can look like “bad filament.”

Dry Box Printing (When It’s Worth It)

If you print PETG, TPU, nylon, or support materials regularly, a dry box during printing is more than convenience. It stabilizes the filament condition across long jobs. Consistency is the real benefit, and it’s what makes profiles repeatable.

🔥 Drying Filament Without Guesswork

Drying is about controlled heat and time, not brute force. The safest approach is to start at a lower temperature, verify improvement, then extend time if needed. Many filaments recover well because moisture effects are physical (water in the polymer), not permanent chemistry.

One practical limit: filament spools can deform if the chamber is too hot, even if the polymer itself could tolerate more. Protect the spool and use stable temperature control.

| Material | Typical Starting Range | What to Watch For |

|---|---|---|

| PLA | Low heat range (often around 35–45°C) | Spool softening, glossy “heat shine,” improvement in stringing |

| PETG | Medium heat range (often around 50–60°C) | Pop sounds disappear, walls become smoother |

| ABS / ASA | Medium-high heat range (often around 60–70°C) | Surface roughness improves; avoid spool warping |

| TPU | Low-medium heat range (often around 40–55°C) | Less “spitty” extrusion, crisper edges |

| Nylon (PA) | Higher heat range (often around 70–85°C) | Big improvement is common; keep it sealed after drying |

| PVA / BVOH | Low-medium heat range (often around 40–55°C) | Clogs reduce; filament feeds more smoothly |

These are intentionally conservative starting ranges because blends and spool materials vary. If a manufacturer provides a drying spec for that exact filament, follow it. Drying is a key step in polymer processing quality, especially for moisture-sensitive materials.[f]

A Simple “Stop Point” That Works

- Extrude a short test strand after drying and look for smooth, uniform flow.

- If the defect pattern is still the same, extend drying time rather than increasing temperature aggressively.

- When the filament behaves well again, seal it right away. Drying without storage is like cleaning a table in the rain.

Why Moisture Claims Vary So Much

“How wet is wet?” depends on how plastics absorb and retain water, and how we measure it. Standards like ASTM D570 exist because water absorption is a real, testable property, but real-world spools also face variables: filament diameter, fillers, ambient humidity, and how long the spool has been exposed.[c]

❓ FAQ

Can I still use filament that has been open for a year?

Often yes. “Open for a year” matters less than how it was stored. If it stayed sealed with desiccant and away from heat/light, it may print normally. If it sat in humid air, drying usually restores performance for many materials, especially PETG and TPU. Moisture history beats the calendar.

Is “popping” always moisture?

Moisture is the most common cause because water can flash into steam in the hotend. But a partial clog or contamination can mimic the same noise and roughness. Drying is a fast way to rule moisture in or out, and it’s usually the first thing worth trying.

Does sealed filament last “forever”?

Sealing dramatically slows moisture pickup, which is the big day-to-day issue. Over very long periods, heat and light exposure can still matter, and packaging isn’t always perfectly airtight. Stored cool, dark, and sealed, many spools remain usable for years in practical printing terms.

Why does nylon feel different when it’s wet?

Water acts like a plasticizer in many polyamides, changing stiffness and behavior. That’s why nylon can print inconsistently when it’s absorbed moisture, and why it often benefits from a dry box during printing. Nylon is built this way; it’s not a “bad filament” problem.

Do carbon-fiber or glass-fiber blends “expire” faster?

They usually follow the moisture behavior of the base polymer (PLA-CF behaves more like PLA; PA-CF behaves more like nylon). Fillers can change texture and wear, but “expiration” in day-to-day printing is still commonly moisture-driven. Keep them sealed and clean, and treat drying like you would for the base material.

📚 Sources

- [a] MDPI Polymers: “Moisture Sorption and Degradation of Polymer Filaments Used in 3D Printing”

- [b] ScienceDirect (Polymer Degradation and Stability): “Hydrolytic degradation of poly(lactic acid)”

- [c] ASTM: D570 “Standard Test Method for Water Absorption of Plastics”

- [d] Springer: “Plastics: Photodegradations and Mechanisms”

- [e] Middle East Technical University Thesis PDF: “Photo-Oxidative Degradation of ABS Copolymer”

- [f] Springer: “Beyond processing methods: the impact of the drying stage…” (PET drying study)

- [g] ScienceDirect: “Water absorption in aliphatic polyamide mixtures”