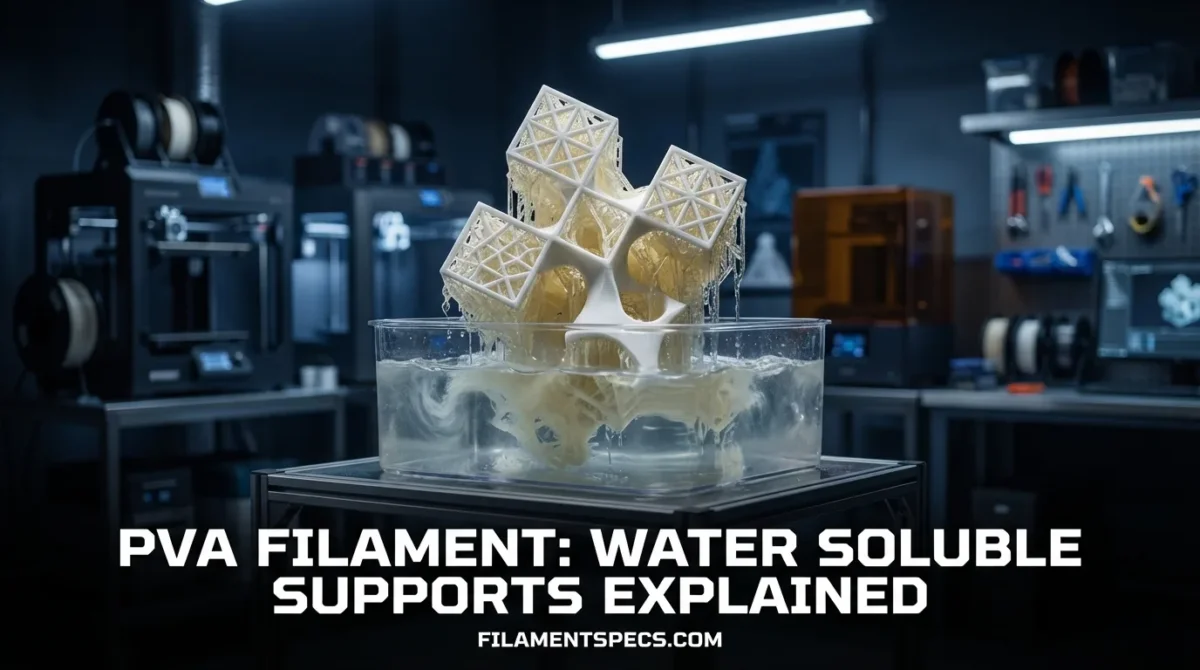

PVA filament is the “support that disappears” when you do dual-extrusion FDM/FFF. It’s built for one job: create clean, stable supports for complex overhangs and sealed internal channels, then melt away in water so the printed model stays crisp. If you’ve ever snapped a fragile PVA strand, fought stringing, or waited hours for supports to dissolve, you already know the truth: PVA is simple in concept and surprisingly technical in practice.

| Spec | Representative Values (Brand Example) | Why It Matters For Water-Soluble Supports |

|---|---|---|

| Core role | Water-dissolvable support material | Support removal shifts from “break and sand” to “soak and rinse” for delicate parts. |

| Recommended nozzle temperature | 220–250 °C | Controls flow, bonding, and how cleanly the support interfaces release after dissolving. |

| Recommended bed temperature | 35–45 °C | Helps first-layer stability without overheating a moisture-sensitive polymer. |

| Drying before printing | 80 °C for 8–12 h (oven) | Moisture can cause bubbling, weak extrusion, and surface defects in support layers. |

| Storage humidity target | < 20% RH (sealed + desiccant) | Keeping it dry is the single biggest factor in consistent PVA printing. |

| Density | 1.27 g/cm³ | Useful for estimating spool usage and support material volume. |

| Melt index (example condition) | 7.2 ± 1.1 g/10 min (210 °C, 2.16 kg) | Hints at flow behavior; different grades can behave very differently in the nozzle. |

| Melting temperature (DSC) | 202 °C | Shows why PVA’s processing window can feel narrow: it’s sensitive to both heat and water. |

| Water absorption (example test) | 6.25% (25 °C, 55% RH) | Explains why open-air printing can drift over time (stringing and brittleness often creep in). |

| Solubility | Soluble in water | Post-processing can be gentle on small features, thin walls, and intricate textures. |

Those numbers are a real-world snapshot from a widely used PVA technical data sheet, meant as a baseline for understanding how PVA behaves as a support filament rather than as a rigid “build” plastic.[a]

Table of Contents

🧪 What PVA Filament Really Is

PVA stands for polyvinyl alcohol, a water-soluble synthetic resin used across multiple industries and adapted for 3D printing as a dissolvable support. One detail matters more than most people realize: PVA isn’t made by polymerizing “vinyl alcohol” directly; it’s typically formed by hydrolyzing polyvinyl acetate. That hydrolysis level shapes how the polymer behaves in water and under heat.

In official specifications, PVA is described in terms of chain length and composition, and it’s commonly prepared by partial hydrolysis of polyvinyl acetate (often around 85%–89% hydrolysis for a defined grade).[b]

Think of PVA filament as a controlled “temporary polymer.” It must be stable enough to print cleanly, yet still willing to dissolve after the job is done. That balancing act is why different PVA brands can feel like totally different materials.

🔬 Why One PVA Behaves Differently From Another

PVA is “PVA,” but the real-world performance depends on chemistry choices that change the day-to-day printing experience. Water solubility is especially sensitive to degree of hydrolysis, molecular weight, and how strongly the polymer chains prefer hydrogen bonding in water.

That’s why two spools can both dissolve in water yet dissolve at very different speeds, and why some grades print smoother while others clog easily. Academic polymer references describe PVA’s solubility as a function of hydrolysis, molecular weight, and bonding behavior, and also note that PVA can show critical solution-temperature behavior in water depending on grade and conditions.[c]

What “grade differences” look like in printing

- Dissolve speed: some supports soften fast but leave gel residue; others dissolve slower but rinse cleaner.

- Thermal stability: higher stability grades resist darkening and nozzle buildup during long prints.

- Brittleness on the spool: a formulation plus moisture history issue; PVA can feel “glassy” when dry and “rubbery” when hydrated.

- Interlayer behavior: the same slicer settings can yield either crisp support towers or soft, smeary walls depending on grade.

🧩 Why Water-Soluble Supports Change What You Can Print

Geometry Wins

- Deep internal cavities that would be impossible to pliers-out.

- Overhangs where support contact must be gentle to protect surface detail.

- Complex assemblies where breakaway supports would stress thin walls.

PVA supports are about access. If you can’t physically reach the support, dissolvable material becomes the cleanest path.

Surface Quality Wins

- Reduced scarring on visible faces (especially on curved or textured surfaces).

- Cleaner underside bridges when supports can sit closer without fear of tearing.

- Less post-processing on fragile models.

Dissolvable supports don’t automatically mean perfect surfaces, but they do remove the “mechanical violence” of snapping supports off.

💦 How Moisture Quietly Changes PVA While You Print

PVA is famously moisture-sensitive, and this is not just a “filament storage” story. Water can act like a plasticizer in PVA, shifting mechanical behavior and thermal transitions. Research on PVA shows that even small water content can significantly reduce strength and lower glass transition behavior, because water disrupts polymer–polymer hydrogen bonding and increases chain mobility.[d]

What that means for 3D printing supports

- Bubbles and sizzling at the nozzle can show up as rough, foamy support walls.

- Stringing increases because the melt becomes less predictable during travel moves.

- Support “mush” can happen when layers stay soft and smear instead of stacking cleanly.

- Brittle snapping is common when filament is very dry and has been bent through tight feed paths.

🖨️ Hardware And Slicer Requirements

PVA shines when your setup can keep the support material consistent across a long job. The most common path is dual extrusion, but the same ideas apply to toolchangers and IDEX systems.

Printer-side basics

- Dry feed path: a sealed dry box or dry feeder matters more for PVA than for many build filaments.

- Stable retraction behavior: PVA is prone to fine strings; consistent motion control helps.

- Reliable purging: avoid contaminating the model’s nozzle with PVA residue (or contaminating PVA with the model material).

If your printer struggles with consistent extrusion over time, PVA will expose it quickly.

On the slicer side, the quality jump usually comes from support-interface control: setting a dedicated interface layer, limiting support density away from the interface, and using purge structures (wipe walls, prime towers) that match your machine’s behavior.

🔥 Printing Settings That Matter Most

PVA settings are less about “one perfect profile” and more about managing a few predictable trade-offs. The goal is stable support geometry that bonds well enough to hold shape, yet dissolves cleanly at the interface.

- Temperature: raise it when layers look under-extruded or weak; lower it if stringing and nozzle buildup dominate. Stay close to your brand’s spec and treat PVA as formulation-dependent.

- Cooling: PVA usually benefits from active cooling to lock in support walls; too much cooling can reduce interlayer bonding on thin towers.

- Speed: fast printing can work when the filament is dry and flow is steady; slow down if supports look “fuzzy” or inconsistent.

- Retraction discipline: keep it controlled; aggressive retractions can grind soft PVA, while weak retractions can turn travel moves into webs.

- Purging strategy: with multi-material printing, clean purges keep interfaces crisp and reduce contamination that slows dissolution.

Support interface tuning (where most of the “magic” happens)

- Use a dedicated support interface layer count (often 2–4) rather than making the entire support dense.

- Keep the interface gap tight enough for surface quality, but avoid “fusing” by testing one small overhang before committing to a full build.

- Prefer a smoother interface pattern when the model surface matters more than speed.

- Let the model material drive bed temperature, then tune PVA around it (PVA often behaves better when it’s not overheated from below).

🧷 Support Design Choices That Save Hours

PVA dissolves in water, but it still obeys geometry. Support design is where you can turn a 12-hour soak into a 2-hour soak. The trick is reducing trapped volume and increasing water access while keeping the print stable.

- Use less PVA on purpose: choose PVA only for the interface (support roofs) and print the bulk support in the same material as the model when your slicer supports it.

- Vent internal cavities: even a small drain/vent hole can transform dissolution speed for enclosed channels.

- Avoid solid “blocks”: thick, fully dense PVA supports dissolve slowly and can become gel-like on the outside while staying solid in the center.

- Prefer tree-like structures when they provide enough contact; they reduce material and improve water flow.

🧵 Material Pairing: What PVA Likes To Support

PVA works best when it can bond to the model material during printing without forcing extreme temperatures or warping behavior. Many widely used PVA support products emphasize strong adhesion to PLA, PETG, and some nylon-based filaments, while noting that it may be non-ideal for higher-temperature or low-surface-energy build plastics depending on the product and setup.[e]

Practical pairing logic

- Closer print temps between model and support usually mean fewer surprises.

- Better inter-material adhesion improves underside surfaces, but too much bonding can slow removal.

- Support is part of the print: if the model material needs a hot chamber, pick a support strategy that survives that environment.

💧 Dissolving PVA Supports Without Making A Mess

Dissolving is chemistry plus logistics. Water temperature, agitation, and access to the support surface matter more than “waiting longer.” Warm water typically speeds dissolution, gentle agitation keeps the boundary layer from turning into a slow gel, and breaking large supports into smaller exposed faces can dramatically reduce time.

A clean dissolution workflow

- Start with a rinse to remove loose support fragments and open water pathways.

- Soak in water that is comfortably warm to the touch (not boiling), then refresh the water if it turns thick or cloudy.

- Agitate occasionally or use a gentle circulation method to keep dissolution active.

- Use a soft brush for stubborn pockets, focusing on exposed faces rather than digging into the model surface.

If the outside turns slimy but the core stays solid, it’s usually a water-access problem, not a “bad PVA” problem.

🚿 After The Water Bath: Where The Dissolved PVA Goes

Many users wonder if dissolved PVA is “okay” in typical wastewater streams. A detailed wastewater-treatment simulation study on a representative nonmodified PVOH grade (18-88) observed high removal during treatment via biodegradation (average reported around 97% in the study’s plateau phase). This is not a claim that every PVA formulation behaves identically, but it’s a useful data point for understanding how water-soluble PVOH can be handled in a realistic treatment context.[f]

A simple common-sense habit still helps: avoid dumping a large, highly concentrated gel all at once. Dilution and steady flow reduce the chance of slow-moving clumps in plumbing.

🫙 Storage, Drying, And Moisture Control

PVA printing quality is often decided before you hit “Start.” Once PVA has absorbed moisture, your slicer can’t fully compensate. The goal is keeping the filament in a stable state: dry enough to extrude cleanly, but not so brittle that it snaps through sharp feed paths.

- Seal it immediately: bag + desiccant, every time. PVA doesn’t “forgive” open-air storage for long.

- Use an active dry system: dry box, dry feeder, or a printer enclosure solution that keeps humidity low during long jobs.

- Dry when in doubt: if extrusion looks foamy, rough, or inconsistent, assume moisture first and retest.

- Avoid sharp bends: brittle PVA can snap if your path includes tight radii or aggressive filament sensors.

Moisture symptoms are sneaky

One print can look fine for the first hour, then slowly degrade as the spool sits in open air. If you notice late-print stringing or supports turning rough over time, humidity drift is a prime suspect.

❓ FAQ

Can I use PVA on a single-extruder printer?

You can print PVA as a material on a single extruder, but it loses its main advantage as a separate support. Without a second tool, you can’t combine PVA supports with a different model filament in the same job. PVA becomes most valuable when the printer can keep model and support materials independent.

Does PVA dissolve in cold water, or does it need heat?

PVA dissolves in water, but temperature and movement usually change the speed a lot. Cold water can work; it’s simply slower. Warm water and gentle agitation often reduce “gel skin” buildup and keep the process moving.

Why does PVA snap and break during feeding?

PVA can become brittle when very dry, and it doesn’t like tight bends. Sharp filament paths, stiff tubes, or frequent reverse motions can turn small cracks into a snap. Reducing bend radius and keeping the feed path smooth usually helps.

What is the biggest reason for PVA stringing?

Moisture is the most common cause. After that, it’s usually a mix of temperature and travel behavior. If PVA is dry and still strings heavily, tune retraction and consider stronger purge/wipe behavior so the nozzle isn’t carrying soft PVA across gaps.

Can PVA support PETG or Nylon reliably?

Often yes, but it depends on the specific PVA grade and your temperature window. PETG and nylon frequently run hotter than PLA, which can stress some PVA formulations. The best approach is matching materials that behave well together at your printer’s operating temperatures and confirming with a small test print before long builds.

How do I speed up dissolving without damaging the model?

Increase water access and refresh the water when it becomes thick. Warm water plus gentle motion is usually safer than aggressive scraping. If the model material is sensitive to heat, keep water temperature moderate and rely more on agitation and water changes.

FAQ Schema (JSON-LD)

{

"@context": "https://schema.org",

"@type": "FAQPage",

"mainEntity": [

{

"@type": "Question",

"name": "Can I use PVA on a single-extruder printer?",

"acceptedAnswer": {

"@type": "Answer",

"text": "You can print PVA as a material on a single extruder, but its main advantage is as a separate support material in multi-material printing. Without a second toolhead, you cannot print a different model filament and PVA supports in the same job."

}

},

{

"@type": "Question",

"name": "Does PVA dissolve in cold water, or does it need heat?",

"acceptedAnswer": {

"@type": "Answer",

"text": "PVA dissolves in water, but warm water and gentle agitation typically speed up the process. Cold water can still work; it usually just takes longer and may form a gel-like layer that slows dissolution."

}

},

{

"@type": "Question",

"name": "Why does PVA snap and break during feeding?",

"acceptedAnswer": {

"@type": "Answer",

"text": "PVA can become brittle when very dry and may snap in tight feed paths or around sharp bends. Smoother filament routing and avoiding aggressive bending helps reduce breakage."

}

},

{

"@type": "Question",

"name": "What is the biggest reason for PVA stringing?",

"acceptedAnswer": {

"@type": "Answer",

"text": "Moisture is a common driver of PVA stringing. If the filament is dry, temperature, travel moves, and retraction behavior are the next most influential factors."

}

},

{

"@type": "Question",

"name": "Can PVA support PETG or Nylon reliably?",

"acceptedAnswer": {

"@type": "Answer",

"text": "Often yes, but reliability depends on the PVA formulation and the printing temperature window. Hotter build materials can stress some PVA grades, so a small compatibility test print is recommended before long jobs."

}

},

{

"@type": "Question",

"name": "How do I speed up dissolving without damaging the model?",

"acceptedAnswer": {

"@type": "Answer",

"text": "Increase water access to the supports, refresh the water when it becomes thick or cloudy, and use warm (not boiling) water with gentle agitation. Avoid aggressive scraping on delicate surfaces."

}

}

]

}Sources

- [a] Bambu Filament Technical Data Sheet V1.0 — PVA (PDF)

- [b] United States Pharmacopeia — Polyvinyl Alcohol (USP-NF Preview)

- [c] Springer — Water Solubility Characteristics of Poly(vinyl alcohol) (Hassan, Trakampan, Peppas)

- [d] DOI — Water Governs the Mechanical Properties of Poly(vinyl alcohol) (Polymer, 2021)

- [e] Ultimaker — PVA Technical Data Sheet v5.00 (PDF)

- [f] Oxford Academic — Wastewater Treatment Simulation and Environmental Fate of PVOH Disposed Down the Drain (2024)