| Storage Variable | What You’re Controlling | What To Measure | Where It Shows Up | Verified Reference |

|---|---|---|---|---|

| Relative Humidity (RH) | Water vapor available to diffuse into polymer | Hygrometer inside the same enclosure as the spool | Extrusion consistency, surface texture, soluble support behavior | UltiMaker notes hygrometer use and mentions keeping humidity below 20% for many filaments; also lists PVA needing RH below 50% under its example storage conditions [a] |

| Temperature | Moisture diffusion rate, softening risk, spool stability | Simple thermometer (inside box if heat sources nearby) | Spool deformation risk (overheating), faster moisture exchange when warm | UltiMaker’s example storage ranges: most filaments -20°C to +30°C, ABS 15–25°C, PVA 10–30°C [a] |

| Light (UV + Sunlight) | Photo-oxidation risk on sensitive polymers and colorants | “Is it exposed?” is often enough | Long-term brittleness, color shift (material-dependent) | “Keep out of direct sunlight” is part of UltiMaker’s manufacturer-style storage guidance [a] |

| Air Exchange (Leaks) | How quickly outside humidity replaces your enclosure air | How stable your hygrometer reading stays | Desiccant life, “it was dry yesterday” surprises | CCI describes sorbents used inside enclosures and highlights monitoring + leakage as core variables in passive RH control [e] |

| Desiccant Capacity | How much water your buffer can hold before it’s “full” | Weight change (best), or indicator behavior (secondary) | How long a sealed setup stays stable | One silica gel indicator product lists absorption capacity at 40% RH as minimum 20% (by weight) [f] |

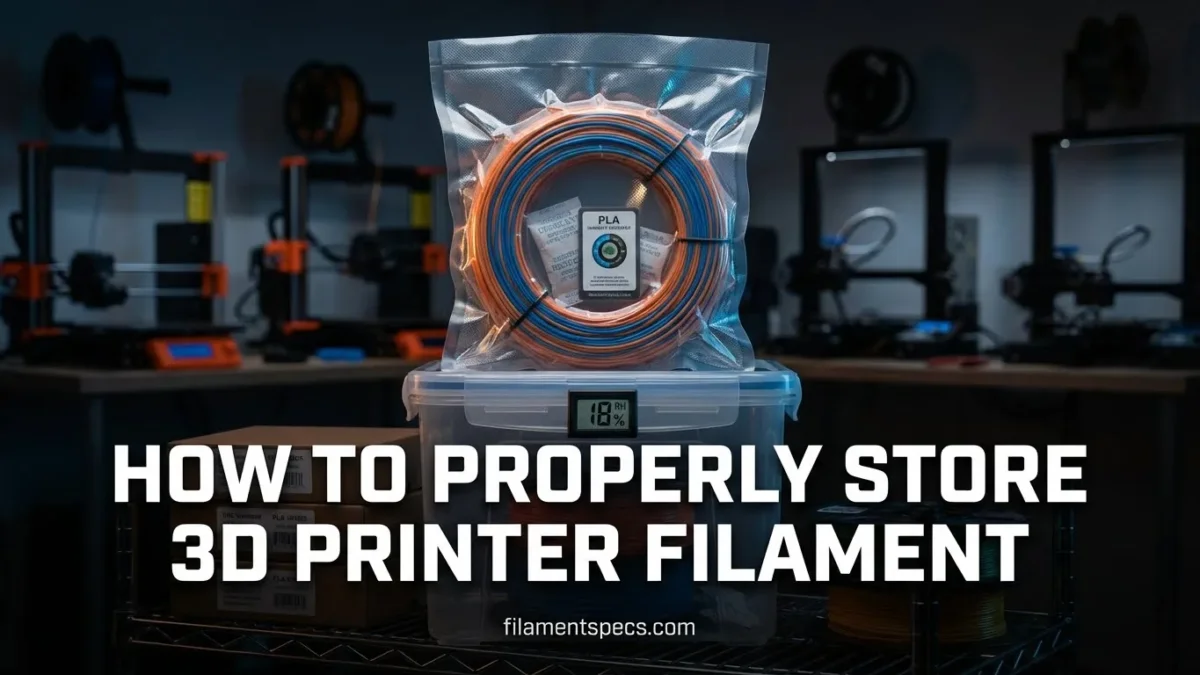

Proper filament storage is mostly environment control in miniature: you’re limiting moisture, smoothing out temperature swings, and keeping light and dust from slowly changing the material. It sounds basic, yet the details matter because a spool isn’t “just plastic” — it’s a long, thin polymer shape with a huge surface area, so it trades moisture with the air faster than most people expect.

Table of Contents

🧭 What Proper Filament Storage Controls

Two Different Goals, One Setup

Prevention is about keeping a dry spool dry by limiting air exchange and buffering humidity. Recovery is about removing water that’s already inside the filament, which typically needs heat and time. When those two goals get mixed up, people expect a sealed bag with desiccant to “fix” wet filament and then wonder why nothing changes.

Storage also protects against slow environmental inputs that don’t look dramatic day-to-day: UV exposure, airborne dust, oils from hands, and constant temperature cycling. None of these are exciting, but they’re real variables when spools sit out for weeks.

💧 Moisture Uptake And Polymer Behavior

Filament moisture is not only “water on the surface.” Water molecules can diffuse into many polymers until they reach a new equilibrium with the surrounding air. That equilibrium shifts with RH and temperature, and thin shapes (like filament) move toward equilibrium faster than thick parts. You’ll often notice the change first during extrusion because water can flash to steam in the hot zone, changing flow and surface appearance in a way that feels sudden even when uptake was gradual.

Some polymer families also have a chemical dimension to moisture. For condensation polymers, hydrolysis can be moisture-dependent, and one NIST-hosted technical document frames a key idea like this: water in the polymer tracks relative humidity, and hydrolysis in polymer film can show a second-order dependence on water availability [c]. You don’t need to model kinetics at home to benefit from this—just understand why stable, low-humidity storage is a genuine material-control step, not a cosmetic one.

Practical translation: “Dry air” matters twice. It slows additional uptake and also reduces the water available for moisture-driven chemistry in sensitive polymers. That’s why consistency in an enclosure often beats chasing a perfect number in an open room.

There’s also a straightforward research signal from the 3D-printing side: a peer-reviewed study focused on nylon filament looked at how different moisture levels relate to printed part properties, treating filament moisture as a measurable variable rather than a vague annoyance [h]. That’s useful framing: moisture is a material state, not a personality trait of the spool.

🌡️ Temperature, Humidity, And Light

- Humidity

- What matters most is the air in the same container as the spool, not a room average.

- Temperature

- Stability beats extremes. Warm air accelerates moisture exchange and can soften some spools and materials.

- Light

- Direct sunlight is a avoidable stressor; shade is a simple long-term win.

Humidity is the big lever because it directly changes how much water vapor is available to enter the polymer. If your storage is leaky, your desiccant becomes a timer; if it’s tight, the same desiccant becomes a stabilizer.

What “Relative Humidity” Really Means

Relative humidity is a ratio: actual water vapor compared to the maximum the air can hold at a given temperature. CCI’s technical bulletin spells this out and then goes deeper into why stable RH inside an enclosure is a controllable engineering problem (monitoring, leakage, sorbent capacity) rather than a mystery [e].

For filament storage, that perspective is gold: the enclosure is your “micro-room,” and you can make that micro-room stable even if the bigger room is not.

🧰 Containers And Barrier Performance

Every storage method is a trade-off between barrier, access convenience, and capacity. A good barrier limits moisture exchange; a good workflow keeps you using the barrier instead of leaving spools exposed. The “best” container is usually the one that stays closed most of the time.

| Container Style | Air Exchange | Moisture Buffer Space | Access Pattern | Where It Shines |

|---|---|---|---|---|

| Resealable bag (thick zip / barrier bag) | Low when sealed well | Small (limited headspace) | Frequent open/close | Single spools, short rotation, keeps dust off |

| Gasketed box (airtight tote) | Low to medium (depends on seal) | Large (room for more desiccant) | Batch access | Multiple spools, consistent storage zone |

| Vacuum bag | Very low (when sealed) | Very small (minimal air inside) | Occasional access | Longer idle periods, compact storage |

| Dry box with feed-through | Low (if ports are tight) | Medium to large | Continuous use while enclosed | Moisture-sensitive filaments during printing |

Leak reality: If your hygrometer reading climbs steadily even when you never open the container, you don’t have a desiccant problem — you have an air exchange problem.

🧪 Desiccants And Moisture Buffering

Desiccants do two jobs. First, they adsorb water vapor so the air in the container stays drier. Second, they buffer the system: when you open the lid and ambient air rushes in, the desiccant smooths the spike instead of letting RH jump and stay there. That “buffer” idea is a big theme in CCI’s enclosure-focused guidance, including how to monitor and keep the RH in a sealed space stable over time [e].

Silica Gel In Plain Numbers

It’s easy to treat silica gel as a magical packet. It’s not magic; it’s capacity. One technical data sheet for humidity-indicating silica gel lists absorption capacity at 40% RH as at least 20% (by weight), which is a concrete reminder that your packet size and your container volume matter [f].

- Capacity is finite; once saturated, RH rises faster after every opening.

- Distribution helps: spread desiccant so air “sees” it, not only the corners.

- Measurement beats guessing: a hygrometer tells you if your setup is stable.

📦 Passive Dry Boxes And Active Dryers

A passive dry box is basically a sealed container plus desiccant and monitoring. An active dryer adds heat (and usually airflow) to push moisture out of the polymer faster. In real usage, many people combine them: actively dry when needed, then store passively so the filament doesn’t drift back toward ambient.

Prusa’s own Drybox description is explicit about this hybrid idea: it uses silica gel to maintain and reduce humidity inside the box, and it still recommends pre-drying the filament appropriately before first placing it in the Drybox for optimum performance [g]. That’s a clean way to separate roles: drying changes the filament state; storage preserves it.

Nice mental model: A sealed box with desiccant is a humidity stabilizer. Heat-based drying is a state reset. Mixing the two expectations is where frustration usually starts.

🧤 Handling, Dust, And Real-World Workflow

Storage quality is only as good as the routine around it. If the spool lives “temporarily” on a shelf, it’s effectively stored in room air. The trick is making the closed state easy: keep the container close, keep the opening method simple, and make the hygrometer visible so you notice drift before it matters.

- Exposure time: long open-air time is a multiplier, especially for moisture-sensitive materials.

- Contamination: dust and oils don’t have to be dramatic to change surface behavior. A sealed bag is also a cleanliness tool.

- Identification: labels help you avoid mixing material families that behave very differently around moisture.

- Spool mechanics: preventing tangles and keeping the end secured is part of “storage,” because it protects the filament geometry as much as the chemistry.

🧬 Material-Specific Notes

Materials Commonly Called Out As Highly Hygroscopic

In a practical filament-focused knowledge-base context, Prusa points out “highly hygroscopic materials” and frames storage as either keeping them in a dry environment or drying them before printing; it also mentions vacuum bags for storage and keeping a desiccant in the bag [b]. That’s a good baseline because it focuses on behavior, not brand.

- PLA / PETG (Polyesters)

- Benefit from dry storage for consistent extrusion; polyester chemistry can be moisture-sensitive under heat.

- TPU

- Often treated as moisture-sensitive in practice; stable enclosure RH reduces variability.

- PVA / BVOH

- Soluble supports are especially sensitive to ambient moisture and storage humidity swings.

- Nylon (PA)

- Moisture uptake can be substantial; it’s one of the clearest cases where storage changes day-to-day printing behavior.

- PC (Polycarbonate)

- Moisture can matter during high-temperature processing; stable, dry storage reduces uncertainty.

- Composites (CF/GF-filled)

- The polymer matrix still sets the moisture behavior; fillers don’t magically remove hygroscopicity.

If you want a concrete, polymer-industry style number to calibrate your intuition: DuPont’s nylon design information ties 50% RH to about 2.8% moisture content and 100% RH to about 8.5% moisture content for one nylon reference condition, and it even discusses the time scales involved for moisture movement in thin sections [d]. That’s not “filament-specific,” yet it explains why nylon spools can feel like they change personality with weather.

FAQ

Is a sealed bag enough for long-term filament storage?

A sealed bag mainly controls air exchange. Long-term stability usually depends on adding a moisture buffer (desiccant) and verifying that humidity inside the bag stays stable with a small hygrometer.

Does desiccant “dry” filament or only keep it dry?

Desiccant primarily lowers and stabilizes humidity in the enclosure. Removing moisture from inside the polymer typically takes time and often benefits from gentle heat and airflow; after that, desiccant-based storage helps preserve the drier state.

Why can filament behave differently even when it “looks fine”?

Moisture effects can be subtle until the filament is heated during extrusion. Water vapor can change flow behavior and surface appearance quickly, so the first obvious signal often appears during printing rather than on the spool.

Which measurement matters most: room humidity or container humidity?

Container humidity. Filament responds to the air it is actually exposed to. A stable, sealed enclosure can stay consistent even if room conditions drift.

Is vacuum storage useful if I already use desiccant?

Vacuum storage reduces the amount of air (and therefore water vapor) inside the package. Desiccant then buffers what remains and helps manage small leaks or residual humidity during storage.

Sources

- [a] UltiMaker — 3D Printer Filament Storage Tips and Tricks

- [b] Prusa Knowledge Base — Drying Filament

- [c] NIST (Hosted Document) — Hydrolysis Kinetics and Lifetime Prediction for Polycarbonate and Polyesters (Pickett)

- [d] DuPont™ Minlon® and Zytel® Design Information — Module II (PDF via Distrupol)

- [e] Government of Canada — Canadian Conservation Institute Technical Bulletin 33: Silica Gel (Passive RH Control)

- [f] Scharlab — Silica Gel With Humidity Indicator (Orange) Technical Data Sheet (PDF)

- [g] Prusa Knowledge Base — Prusa Pro Filament Drybox

- [h] MDPI — Influence of Filament Moisture on 3D Printing Nylon

- [i] YouTube — CNC Kitchen: Filament Storage / Hygroscopic Materials (Video)